Product Introduction

Tristar High Efficiency Filter Separator, utilizes the technology of American high efficiency filter element and double pocket vane assembly, widely apply the separation of liquid and solid from gas in the area of coal chemical, petrochemical, chemical and oil refinery etc.

High efficiency filter separator is a kind of gas, liquid and solid filter separator with multiple filter elements, which can be used to remove the liquid and solid impurities in the gas phase fluid, and ensure a small pressure drop in the process of filtration and separation.

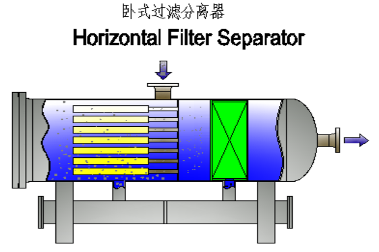

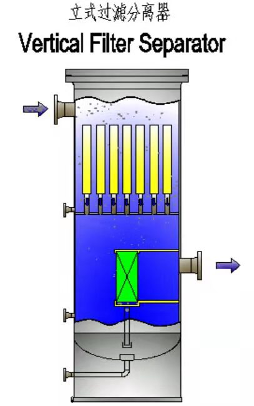

This filter can be divided into vertical high efficiency filter separator and horizontal high efficiency filter separator. The separator is divided into two-stage structure, the first stage is filter element assembly filtration, the second stage is high efficiency vane assembly separation, two-stage filtration separation ensures high separation efficiency.

Performance Guarantee

- 100% solid & liquid particle separation 1 microns and larger;

- Liquid carryover from the outlet gas will be less than 0.001kg/1,000Nm3;

- Pressure drop through the complete separator will be less than 13 kpa under normal conditions (When the filter element is clean);

- The pressure drop of filter element replacement generally does not exceed 100kpa.

Application Examples

- Technip Ningxia Hanas Gas Station Project;

- Salof China Mini LNG Project;

- Petrochina Changqing Oil Field Project;

- Petrochina East West Gas Pipeline Project Phase II, East Section;

- Petrobras ROTA-3 Project;

- Pakistan HMC Gas Development Project;

- Bangladesh TITAS Natural Gas Pipeline Project.

Technical Advantages

- It has high separation accuracy for solid and liquid impurities;

- High efficiency filter element imported from USA;

- Vessel can be arranged horizontally, or vertically;

- Install end quick opening closure for the convenience of the vessel cleaning and filter element replacement;

- High performance, low pressure drop;

- Filter length from 12 inches to 72 inches, diameter from 2.0 inches to 4.5 inches, wide selection, with freedom;

- The use of Tristar patented double-bag high efficiency vane internal assembly, so as to improve the separation accuracy.

Working Principle

Tristar high efficiency filter separator relies on high efficiency filter element assembly and high efficiency annular-vane assembly to realize gas, liquid and solid separation.

After the gas containing liquid-solid impurities enters the filter separator, two-stage filtration separation is carried out.

The first stage is filtration by filter element assembly. Under the action of external force, the fluid passes through the filter material with porous medium channel. In this process, impurities are trapped on the filter medium, so as to realize the operation of gas, liquid and solid separation.

The metal framework in the filter element is used to support the filter material. The folded filter material can increase the actual filtration area, so that the mixed fluid can still achieve higher separation efficiency and lower pressure drop under the premise of higher apparent filtration rate. The driving force driving the mixed fluid through the filter medium is generally the pressure difference.

The second stage is efficient separation using efficient annular vane assembly. In the process of mixed fluid passing through the high efficiency annular vane assembly, the liquid is trapped by the vane blade and flows downward into the water tank under the action of gravity, and the clean gas is discharged from the upper outlet of the separator.

The design of reinforcing rib plate of filter element can reduce the deformation of filter element, and the design of quick-opening-closure and variable-diameter-head can simplify the operation and save space.

The high efficiency annular vane assembly is one patented internals product of Tristar company, which has high separation effect, low pressure, and only 210mm thickness, saving equipment space.