Product Introduction

Tristar Dry Gas Filter utilizes multi quantity filter elements to filtrate the solid from gas with small pressure drop.

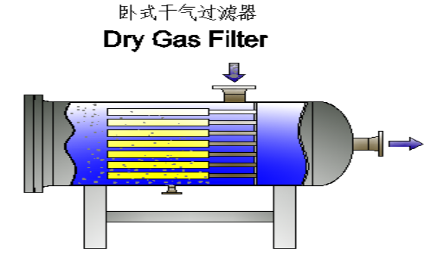

This Filter can be divided into vertical dry gas filter and horizontal dry gas filter. When there is no liquid in the process fluid, it is unnecessary to consider the liquid corrosion when selecting the filter model. Therefore, it is very economical to select this dry gas filter. Tristar dry gas filter is widely used in petrochemical, coal chemical, oil refining, chemical fertilizer and natural gas fields.

Performance Guarantee

- 100% solid particle separation 3 microns and larger;

- Pressure drop through the complete filter will be less than 13 kpa under normal conditions (When the filter element is clean);

- The pressure drop of filter element replacement generally does not exceed 100kpa

Application Examples

- Inner Mongolia Group 1.25 MTPY Ammonia & 2.4 MTPY Urea Project;

- Petrobras ROTA-3 Project;

- Iran Lordegan Fertilizer Project;

- Petrochina Shaanjin Gas Pipeline Phase 4 & East West Gas Pipeline Phase III Project;

- Bangladesh TITAS Natural Gas Pipeline Project.

Technical Advantages

- It has high separation precision for solid particle impurities;

- High efficiency filter element imported from USA;

- Vessel can be arranged horizontally, or vertically;

- Install end quick opening closure for the convenience of the vessel cleaning and filter element replacement.

Working Principle

Tristar dry gas filter relies on the dry gas filter element to realize gas-solid separation.

After the dry gas containing dust enters the filter, under the action of external force, it makes the fluid pass through the filter material with porous medium channels. In this process, the solid particles are trapped on the filter medium, so as to realize the operation of gas-solid separation.

The metal framework in the filter element is used to support the filter material. The folded filter material can increase the actual filtration area, so that the mixed fluid can still achieve higher separation efficiency and lower pressure drop under the premise of higher apparent filtration rate. The driving force driving the mixed fluid through the filter medium is generally the pressure difference.

The design of reinforcing rib plate of filter element can reduce the deformation of filter element, and the design of quick-opening-closure and variable-diameter-head can simplify the operation and save space.