Product Introduction

Tristar high efficiency coalescer separator, utilizes the technology of American high efficiency coalescer cartridge, with combination of core double pocket vane and multi-cyclone assembly, widely apply the coalescing the liquid and solid from gas in the area of coal chemical, petrochemical, chemical, oil refinery and natural gas pipeline etc., so as to get high purity process gas.

High efficiency coalescer separator is a kind of gas, liquid and solid coalescer separator with multiple coalescer elements, which can be used to remove the liquid and solid impurities in the gas phase fluid, and ensure a small pressure drop in the process of coalescer filtration and separation.

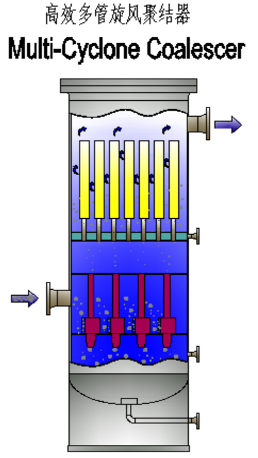

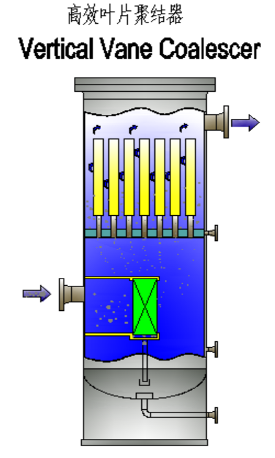

This high efficiency coalescer can be divided into three types: single-stage high efficiency coalescer, vane high efficiency coalescer and multi-cyclone high efficiency coalescer.

High efficiency coalescer adopts the combination form of coalescer filter element assembly and high efficiency separation internal assembly, which can greatly improve the separation accuracy, protect the coalescer elements, so as to increase the service life of coalescer elements, and save the purchase cost of spare parts. It has been widely used at home and abroad.

Performance Guarantee

- 100% solid & liquid particle separation 0.3 microns and larger;

- Liquid carryover from the outlet gas will be less than 0.001kg/1,000Nm3;

- Pressure drop through the complete separator will be less than 13 kpa under normal conditions (When the coalescer element is clean);

- The pressure drop of coalescer element replacement generally does not exceed 100kpa.

Application Examples

- Petrochina East West Gas Pipeline Project Phase II Eastern Section;

- Petrochina Dalian-Shenyang Gas Pipeline Project;

- Petrochina Shandong Gas Pipeline Network Project;

- Inner Mongolia Wulan Fertilizer Project;

- GE Oil & Gas Turkey Salt Lake Gas Storage Station Project;

- Technip Ningxia Hanas Gas Treating Plant Project.

Technical Advantages

- It has high separation accuracy for solid and liquid impurities, based on the separation performance requirement, Tristar can combine its vane technology, or multi-cyclone technology together with coalescer to meet the performance;

- High efficiency coalescer element imported from USA;

- Install end quick opening closure for the convenience of the vessel cleaning and coalescer element replacement;

- High performance, low pressure drop;

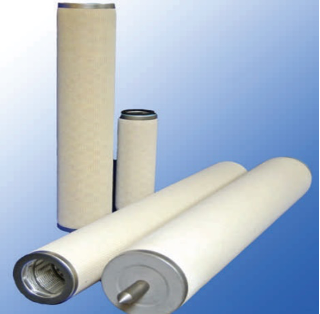

- The coalescer element length from 12 inches to 72 inches, diameter from 2.0 inches to 4.5 inches, wide selection, with freedom

Working Principle

Tristar high efficiency coalescer separator relies on high efficiency coalescer filter element and high efficiency mechanical separation internals to realize gas, liquid and solid separation. The flow direction of the mixed fluid is generally from the inner surface to the outer surface of the coalescing filter element.

The single-stage high efficiency coalescer only uses coalescer filter element assembly for filtration separation. After the gas containing liquid-solid impurities enters the coalescer separator, the coalescer filter element coalesces and grows the liquid mist to realize the separation of the liquid mist from the gas. In this process, solid impurities will deposit on the surface of coalescer filter elements. Therefore, this type of high-efficiency coalescer requires that the solid content in the feed is not too much, too much solid impurities will lead to frequent replacement of the coalescer elements.

The vane high efficiency coalescer is two-stage filtration separation. After the gas containing liquid-solid impurities enters the coalescer separator, the first stage uses the high-efficiency vane internals assembly to roughly separate the mixed fluid. High efficiency vane can separate large droplets and agglomerate liquid mist. In the second stage, high efficiency coalescer filter element is used to coalesce and grow the liquid mist to realize the separation of the liquid mist from the gas.

The multi-cyclone high-efficiency coalescer is a two-stage filtration separator. After the gas containing liquid-solid impurities enters the coalescer, the first stage uses the high-efficiency multi-cyclone internals to roughly separate the mixed fluid. High efficiency multi-cyclone can separate solid particles and liquid impurities of various sizes. In the second stage, high efficiency coalescer filter elements are used to coalesce and grow the liquid mist to realize the separation of the liquid mist from the gas. This type of high efficiency coalescer can deal with the gas, liquid and solid mixture with high dust content and achieve high separation accuracy.

The coalescer filter element is generally composed of three parts: the first layer is the folded cellulose coalescence layer, which is located in the glass fiber drainage layer, which can coalesce 100% droplets larger than 0.3 μm; The second layer is the drainage layer, which is made of very thin glass cloth, which can retain and discharge the liquid, and prevent the liquid coalesced from entering the gas again; The third layer is a metal framework layer with holes inside, which can guarantee the mechanical strength of the coalescer filter element.

For the selection of the size and quantity of coalescer filter element, Tristar has rich experience and strict calculation formula. When we select the coalescer element, the momentum passing through the coalescr filter element surface must be less than 0.25 kg / m.s2; The momentum through the effective cross section of the coalescer equipment must be less than 373 kg / m.s2; The momentum passing through the effective surface area of high efficiency vane assembly must be less than 67 kg / m.s2.

The metal framework in the coalescer filter element is used to support the coalescing material. The folded filter material can increase the actual filtration area, so that the mixed fluid can still achieve higher separation efficiency and lower pressure drop under the premise of higher apparent filtration rate. The driving force driving the mixed fluid through the coalescer filter medium is generally the pressure difference.

The design of reinforcing rib plate of coalescer filter element can reduce the deformation of filter element, and the design of quick-opening-clossure and variable-diameter-head can simplify the operation and save space. Both high efficiency vane assembly and high efficiency multi-cyclone assembly are patented internal products of Tristar company, with high separation effect and low pressure.