Product Introduction

We have our own patent for high efficiency vane separator, it is widely recognized by the buyers in the chinese and abroad markets.

Tristar High Efficiency Vane Separator utilizes American core technology of double pocket vane element, widely apply on the area of coal chemical, petrochemical, chemical and oil refinery which there is gas/liquid separation with big flow rate, especially widely use on carbon monoxide conversion, compressor inlet, intermediate, outlet, methanol fabrication, methanol low temperature wash etc. in coal chemical process.

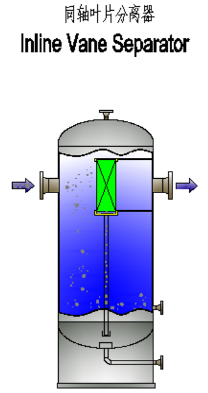

Vertical Inline Vane Separator: the inlet and outlet are on the same axis, which can save installation space.

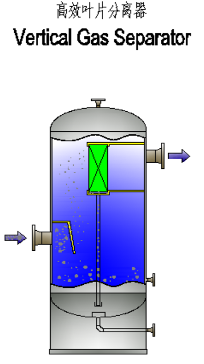

Vertical Vane Separator: compact structure, single-plate type and four-plate type can be used as internals assembly.

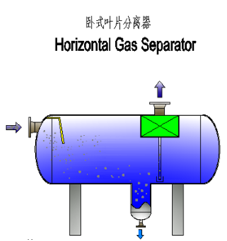

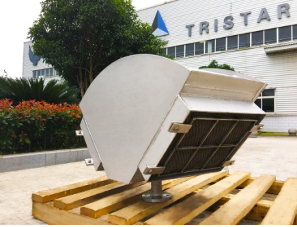

Horizontal Vane Separator: V-plate type vane assembly

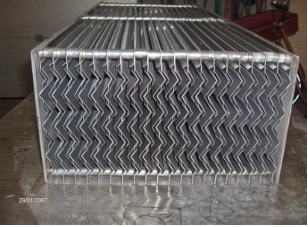

The type classification of high efficiency vane internal assembly is as follows:

Performance Guarantee

- 100% liquid particle separation 8 microns and larger;

- Liquid carryover from the outlet gas will be less than 0.01kg/1,000Nm3;

- Pressure drop through the complete separator will be less than 7 kpa under normal conditions.

Application Examples

- Methanol Separator for Shenhua Ningmei coal to Methanol Project;

- Gas Liquid Separators for Shanxi Lu’an Coal to Oil Project on Fischer-Tropsch Synthesis Unit;

- Compressor Inlet/Intermediate/Outlet Separators for Petrochina Yunnan oil Refinery Project;

- Bangladesh Margaret 589.75MW Gas Fire/541.22 Oil Fire Combine Cyclone Power Plant Project Vane Separator

Technical Advantages

- Can handle very big gas/liquid flow rate, and get ideal gas-liquid separation performance;

- Vessel size can be optimized which is typically 30-40% smaller than conventional separator technology;

- Set up liquid collecting device and downcomer to avoid backmixing and gas-liquid secondary entrainment;

- High separation efficiency with low pressure drop;

- Vessel can operate continuously with any spare parts to replace;

- Process internals can be designed as removable configuration which can be dismantle and installed back from man way for cleaning purpose.

Working Principle

High efficiency vane separator uses the principle of mechanical impact and adhesion to separate gas-liquid mixture. Tristar High Efficiency Vane Separator is designed for the removal of large amounts of liquid. Tristar vane element is designed for maximum performance at low pressure drop.

The gas-liquid mixture has a certain density difference, which is the basis of the mechanical separator. When the liquid content is large, it can first enter the vane-type distributor for coarse separation, and then enter the high efficiency vane internal assembly for fine separation.

After entering the Vane internals assembly, the gas-liquid mixture will collide with the bags and hooks of the high efficiency vane. After collision, the liquid flows into the bottom of the vae assembly, and the clean gas is discharged from the equipment after passing through the vane assembly.

The downcomer system at the bottom of the equipment can effectively avoid the secondary entrainment of gas-liquid mixture and ensure the separation accuracy.