Product Introduction

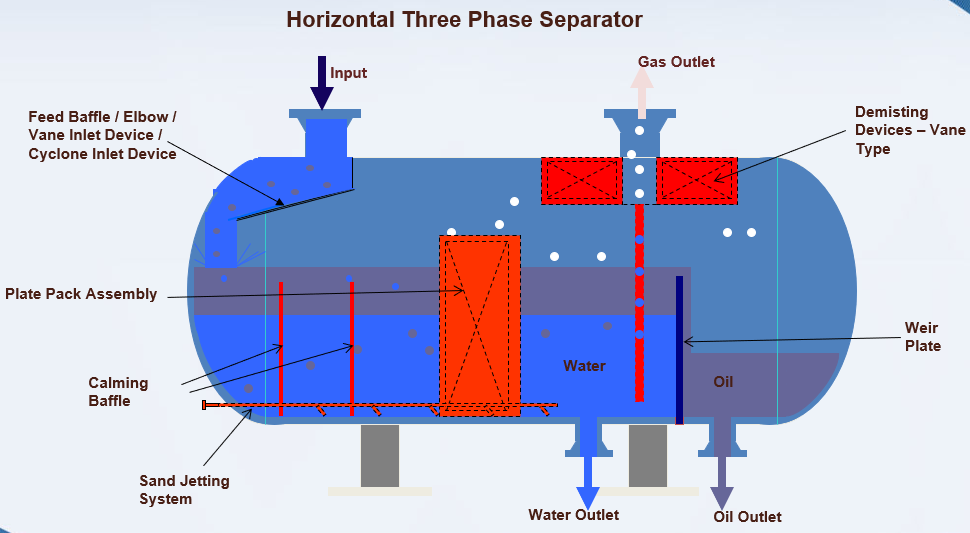

Tristar three phase separator, widely apply on the field of petrochemical, oil refinery and offshore platform etc., mainly for the purpose of oil, water and gas separation. It is usually designed as a horizontal structure.

Tristar three-phase separator uses gas-liquid separation components and oil-water liquid separation inclined plate, which is more compact than the traditional gravity three-phase separator, improves the separation efficiency, reduces the design size, and improves the economic benefit.

Three Phase Separator Including the Following 2 Categories:

- Traditional Three Phase Separator: Oil water separation by gravity, gas liquid separation by vane separation internal, so as to achieve oil, water and gas separation. Separation operation is achieved by the adjustment of position gauge, level gauge and valve opening.

- Oil Water Coalescing Tilted Plate 3-phase Separator: Separate the oil and water with tilted plate coalesce assembly, and separate liquid from gas with vane assembly so as to achieve oil, water and gas separation, the actual operation can be automatically adjusted by dual weir plate, the oil-water separation efficiency is improved and the vessel design size is reduced.

Performance Guarantee

- 100% liquid particle separation 8 microns and larger;

- Liquid carryover from the outlet gas will be less than 0.01kg/1,000Nm3;

- Oil content in the outlet water less than 20 mg/L;

- 100% separation of oil in water 20 microns and larger;

- Water content in outlet oil less than 50 mg/L;

- 100% separation of water in oil 35 microns and larger;

- Usually pressure drop through the complete separator will be less than 10 kpa.

Application Examples

- Shanxi Lu’an Mining Group Integration Demonstration Project;

- Petrobras Rota-3 Project;

- USA Texas West Ranch CO2 Oil Enhancement Recovery Project;

- Iraq Khurmala Dome Development North Degassing Station Project

- Nuoweixin USA Oil Field Project.

Technical Advantages

- Tristar three-phase separator effectively realizes the three-phase separation of oil, water and gas with high separation accuracy and low pressure drop;

- The three-phase separator with coalescing inclined plate optimizes the equipment size of the separator, which is smaller than that of the traditional three-phase separator;

- The equipment can be operated continuously without spare parts;

- The bottom of the equipment is equipped with a sand spraying system to discharge the sand out of the equipment regularly, which can effectively prevent the accumulation of solids. the equipment has online cleaning function;

- The double weir plate has the function of automatic liquid level regulation without manual operation.

Working Principle

Tristar Oil Water Coalescing Tilted Plate 3-phase Separator, separate the oil and water with tilted plate coalesce assembly, and separate liquid from gas with vane assembly so as to achieve oil, water and gas separation, the actual operation can be automatically adjusted by dual weir plate, the oil-water separation efficiency is improved and the vessel design size is reduced.

When the mixed fluid of oil, water and gas enters into the three-phase separator, it first passes through the feed distributor for coarse separation, so as to realize the coarse separation of the liquid from the gas and the momentum redistribution of the mixed fluid.

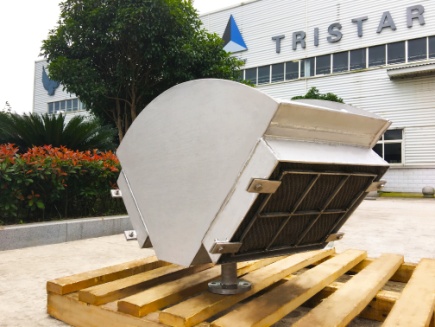

The gas reaches the gas outlet through the upper space of the separator. We set a high efficiency vane-type gas-liquid separation internal assembly at the gas outlet to realize high efficiency gas-liquid separation.

Oil and water are separated through the lower space of the separator, and the basic principle of separation is still gravity stratification. The steady-flow-orifice at the bottom of the three-phase separator can effectively prevent the turbulence of liquid, so as to ensure the gravity stratification of oil and water in laminar flow state.

The oil-water separation and coalescence inclined plate is a set of core oil-water separation internal assembly of Tristar three-phase separator. It divides the larger oil-water separation space into a large number of small spaces. In each small space, the oil-water 2-phase gravity stratification is carried out, so as to reduce the overall residence time of the oil-water stratification, so as to reduce the size of the equipment, and improve the economic benefits.

The bottom of the equipment is equipped with a sand spraying system to discharge the sand out of the equipment regularly, which can effectively prevent the accumulation of solids. The weir plate is set in the back half of the equipment to realize high-efficiency separation of oil and water through accurate automatic control.